The Iittala glass factory has completed the first giant glass domes to be used in the historic lighting fixtures of Turku Castle. Over the decades, lighting domes have been cracked and broken in the castle.

At the Iittala glass factory in Hämeenlinna, large and heavy lighting domes are in the works for Turku Castle. They are about half a metre in diameter and up to 80 centimetres high.

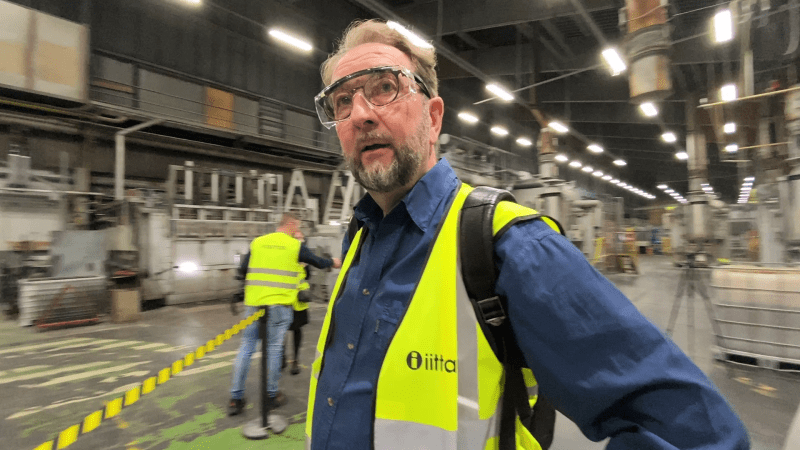

The last time these glass bubbles, weighing around 25 kilograms, were produced at the factory was in 1994. There are no longer any skilled workers at the factory, so the factory had to relearn how to make the bubbles.

Had to learn how to make giant bubbles

Some of the workers at the Iittala glass factory had never even seen such large products being made.

One training day was held in the fall, where knowledge was transferred to the next generation of creators.

– Here we wrestle with a very large amount of glass. There is about 25 kilos of glass at the end of the blow whistle. If the technology is not in control, the mass will take the author with it, explains Välimaa.

The lungs of the fans are not enough

Now huge glass domes are being made in Iittala, which will be used in the Queen’s Hall and the lobby of the main castle. There are two models of glass domes, round and cylindrical.

In Iittala’s factory hall, it takes just under half an hour to make one dome. The author team has at best 7–8 professionals. During the process, the blowers on the whistle often change, otherwise the physics will be too hard. Sometimes you have to use compressed air as an aid when human lungs are no longer enough.

– The more mass there is, the more difficult it is to control the temperature of the glass. In such extreme masses, the temperature variation is different compared to what is done in normal production, explains Tero Välimaa about the challenges of glass manufacturing.

Architect Tapani Mustonen is overjoyed when a discovery from the archives of the Iittala factory is brought before him. It has the original drawings of the wooden glass molds.

– This is Finnish cultural heritage, design and know-how from start to finish. It is good that in Iittala we can practice, make and maintain tradition with these glass domes as well.

The original wooden mould was retrieved from the museum

The original wooden mold of the Queen’s hall was found nearby. It had been on display at the Design Museum in Iittala for decades. The dry wooden mold was allowed to soak in water for a long time before it was dared to be used.

– The wooden mold must be soaked in water so that it can withstand hot glass, Tero Välimaa knows.

The whole glass dome project started more than a couple of years ago. First, all the documents related to the making of large glass domes over the decades were searched for and analyzed.

It took a lot of time to create the right colored glass mass. It had to be just right, slightly yellow-green and full of little air bubbles.

– Lamp domes have been previously blown for the castle in 1957, 1961, 1973 and 1994. There are small differences between these blown batches, although here in Iittala there are glass recipes, Tapani Mustonen admits.

Nowadays, air bubbles are made in lampshades by sprinkling ash on top of a hot glass ball. In the past, they dared to throw wooden blocks into the glass mass.

Luminaires in Turku Castle break down from time to time

This time, 20 cylindrical domes and 15 spherical domes are made in Iittala. Turku Castle should be able to manage with them for a while again.

Sometimes valuable, mouth-blown, heavy glass domes break in the castle.

– Disintegrations usually happen in such a way that on some occasion, for example, a light pole of a roudar or something similar takes and knocks the lampshade to pieces. This is why new domes are needed, explains Tapani Mustonen.